Yatong PE Agriculture Film PP Woven Bags Recycling Machine / Crushing & Washing Machine /Recycling Line

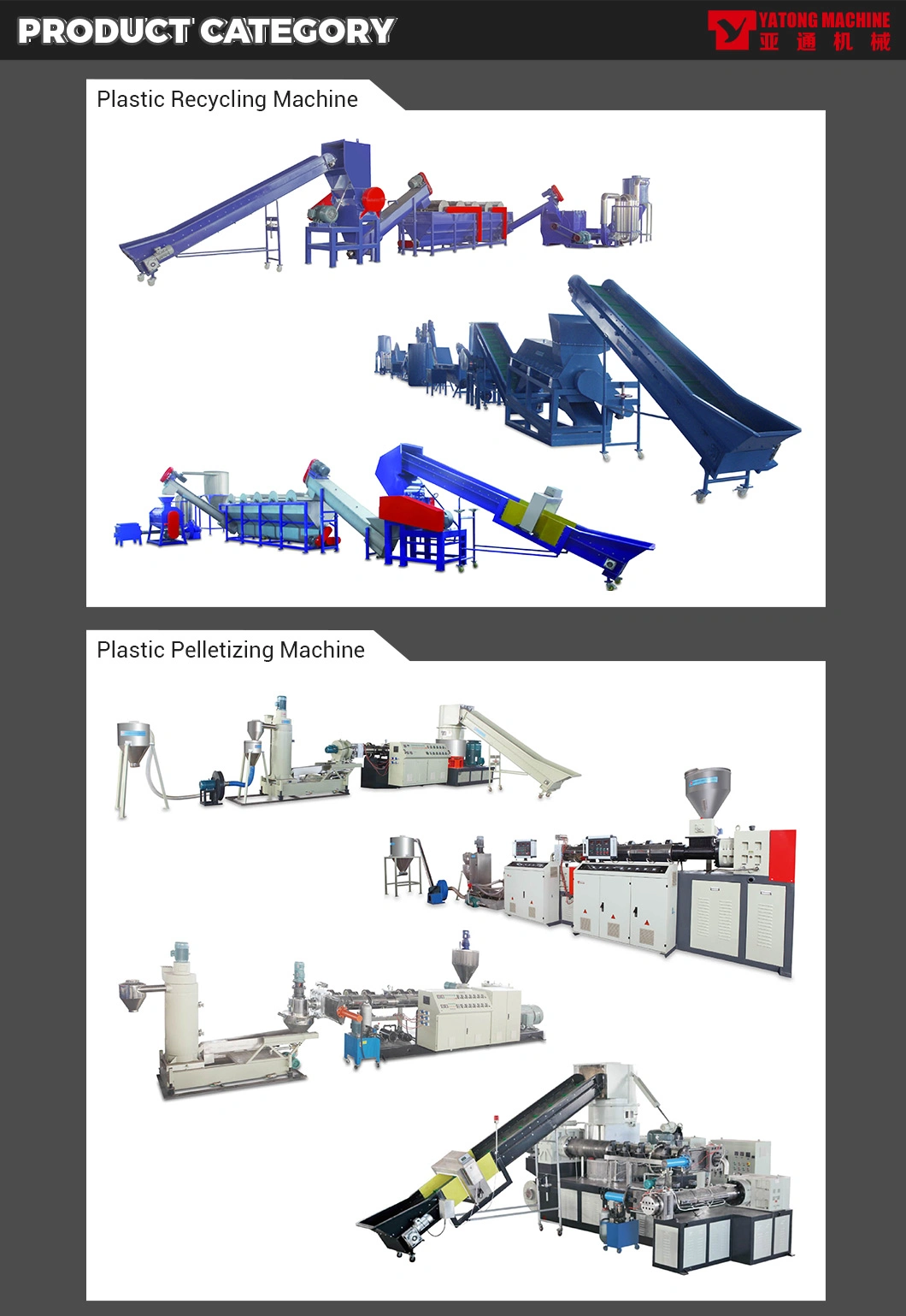

PE film washing equipment is an important step towards improving the environment and reducing carbon footprints. Our film washing machine is designed to recycle different kind of dirty films , like green house film , agriculture film , ground film , woven sack bag , etc. after washing , usually the material will go for further process-pelletizing and then the granule can be used to make different kinds of plastic products.

Working Process:

| Machine List | Function |

| Belt conveyor | Convey waste plastic into crusher |

| Crusher | With water, will cut waste plastic into small piece |

| Screw Conveyor | Convey small pieces |

| Floating Washing Tank | Separate PP PE and PET, dirty according to specific density |

| Screw Conveyor | Convey small pieces |

| high speed frication washer | Scrubbing material in high speed with water |

| Screw Conveyor | Convey small pieces |

| Dewatering Machine | High speed centrifuge drying |

| Drying System | Electric heating wind drying |

| silo | Store the final material |

| Electrical Control Panel | Adopts Siemens and Schneider as main component. |

Features :

a) Easy to opeating the machine

b) after washing the film is very clean to make granule

c) save power and need less worker

d) it is convenient to maintain the machine

Specification :

| Technical Parameter | Model | YT500KG | |

| Belt conveyor | Motor power | 2.2kw | |

| Length | 5-6m | ||

| Crusher | Motor power | 45kw | |

| Crushing chamber size | 1000mm*600mm | ||

| Rotation blades | 6pcs | ||

| Fixed blades | 4pcs | ||

| Blades material | 9Crsi | ||

| Crushing mesh size | Ø80mm | ||

| Capacity | 500kg/h | ||

| Friction washing machine | Motor power | 5.5kw | |

| Rotation speed | 500rpm | ||

| Length | 3000mm | ||

| Diameter | Ø250mm | ||

| Material | All elements contact with water is stainless steel | ||

| Floating washing tank | Tank length | 6000mm | |

| Floating motor | 2.2kw*2pcs | ||

| Discharge dirty motor | 1.5kw | ||

| Screw conveyor | Motor power | 2.2kw | |

| Diameter of main axis | Ø250mm | ||

| Capacity | 500kg/h | ||

| Film Dewatering machine | Motor power | 45kw | |

| Rotation speed | 1200rpm | ||

| Capacity | 300kg/h | ||

| Air blowing system with silo | Heating power | 60kw | |

| Air-inlet motor | 7.5kw | ||

| Air transportation pipe diameter | Ø219 | ||

| Silo volume | 1m3 | ||

REMARK : if the equipment or technological parameters have some change , we shall not make a notice separately .

Application : make PE PP granule then produce PE PP pipe

Advantage :

1- lower power cost , need only one worker is enough to operate the machine

2- hight efficiency , less power consumption

3- High Capacity

Our Services

1. Our factory provide machine testing when customer come to our factory to see this machine.

2. We provide detail machine technical specification, electric diagram, installation book, operating manual, drawings.

3. We can provide engineers to customer's factory to help installation and training workers if customer required.

4.Spare parts is available when u need.within warranty,we will provide without any charge.Over warranty,we can provide spare parts just with factory cost.We will take response and provide technical support and repair of the whole machine lifetime.